STIB, the aluminium machining expert for customized solutions

Machining aluminium profiles is our core business. Our skilled teams and state-of-the-art equipment enable us to meet the most demanding requirements.

Recognized expertise in machining aluminium sections

Founded in 1971, STIB is a benchmark in aluminium profile machining. We offer a complete service, from design to delivery, ensuring customized solutions.

Our in-house design office draws on its R&D expertise to design customized solutions. Our quality laboratory guarantees reliable products thanks to rigorous controls.

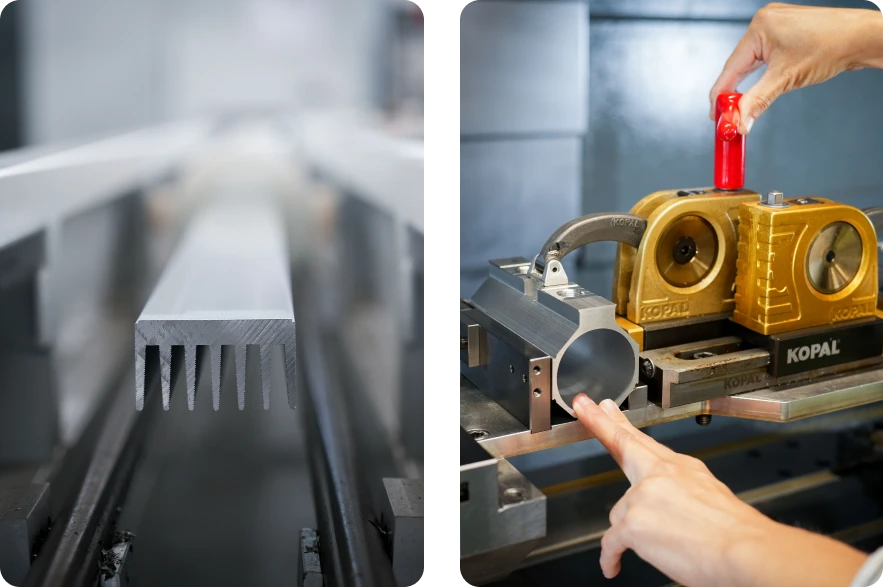

CNC cutting & machining

Laser engraving

Assembly

Manufacturing processes tailored to each project

We use a full range of manufacturing processes to transform profile bars up to 6m in length into technical parts, tailored to the specific needs of each customer and industrial sector.

Our 4- and 5-axis machining centers and state-of-the-art equipment guarantee maximum productivity while meeting the highest quality standards.

We handle surface treatment (sandblasting, anodizing, painting, …), laser engraving and assembly to provide you with a complete product.

Why choose us for your aluminium parts?

Imagine a partner who understands your performance and sustainability requirements. Our strength lies in the technical and economic optimization of the solutions and alloys we propose, enabling your projects to become industrializable, on both a small and large scale.

With a production capacity of several million machined parts every year and recognized know-how, we are the ideal partner to guarantee the success of your industrial projects.

Resources at your service :

- Production area of over 2,500m² ;

- 4- and 5-axis CNC machining centers ;

- Storage of profiles and finished products for greater reactivity.

Our aluminium profile machining projects

Electrical connection

Sports and leisure

Photovoltaic

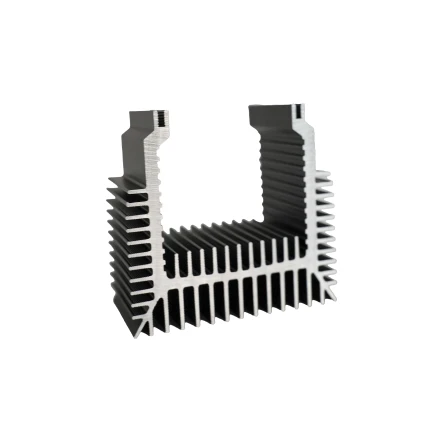

Heat sink

Mobility

Launch your projects with STIB!

Contact us for a personalized quote and find out how our expertise can meet your aluminium machining needs!

What is aluminium machining?

Aluminium machining is a mechanical manufacturing process that transforms aluminium blocks, sheets or profiles into finished, ready-to-use parts, using various cutting, drilling, milling or turning techniques. Using numerically-controlled (CNC) machines, this process produces high-precision parts to exacting technical specifications.

Why choose aluminium for machining?

Aluminium is one of the most popular materials for machining in the industry, thanks to its unique properties:

- Lightweight: With a density around three times lower than that of steel, aluminium is ideal for applications where weight is a key factor, such as aerospace and automotive applications.

- Corrosion resistance: Aluminium alloys offer excellent resistance to oxidation, making them ideal for outdoor or damp environments.

- Thermal and electrical conductivity: Aluminium is commonly used for applications requiring rapid heat dissipation, such as heat sinks, or for electrical components thanks to its exceptional conductivity.

- Malleability: This metal is easy to machine, enabling you to create complex shapes while retaining good mechanical strength.

- Durability and recyclability: Aluminium is robust, long-lasting and can be fully recycled without loss of properties.

Advantages of CNC machining for aluminium

CNC (Computer Numerical Control) machines are essential in aluminium machining because of their ability to :

- Guaranteeing extreme precision, even for the most complex parts.

- Perfect repeatability, essential for mass production.

- Save time thanks to high execution speeds.

- Offer exceptional surface finishes, ready for use or further processing.

They trust us